Lab Suite Equipment for Blood Spot Testing

THE CHALLENGE

Expanding the volume and frequency of diagnostic testing, even among patients in underserved or remote locations, enables new healthcare delivery models that lower costs. Weavr Health had just such an innovation, a platform that revolutionized blood collection beyond the point of care, including patients’ homes. Their unique blood spot test needed the means to make it more desirable and scalable with test processing labs. With many incumbent test technologies already in place at labs, it would take a systems approach with enhanced speed and workflow, making the Weavr technology attractive enough to incorporate into existing lab workflows.

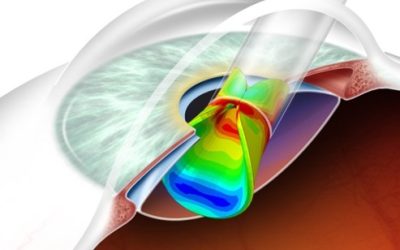

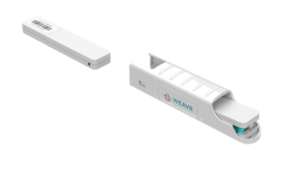

Weavr’s blood collection devices consisting of the “Silk” and “Velvet” test kits, provide fast and easy blood collection to be performed anywhere, whether for transport to a lab, onsite doctor’s office, or a rapid test at home. These kits allow for easy collection of blood samples onsite with a phlebotomist or self-collection. The samples collected are then deposited on a proprietary membrane that separates various parts of the blood. The sample is secured within the device for transportation and patient security. Finally, the membrane is removed from its housing at the test facility and processed at the lab for various diagnostic tests. Although the blood collection kits were designed to provide a positive experience for the phlebotomist or home user, opening and processing the kits in the lab was not easy or streamlined. Many lab technicians found it arduous or even physically painful to open the kits, especially at high volumes, making it challenging to meet membrane processing demands.

To help Weavr succeed with technicians and patients,

SES Force-4 developed a suite of lab equipment focused on a seamless, user-friendly workflow for mid-volume labs processing 100-1,000 samples/day. This process integrated the manual workflow opening of Generation 1 Velvet devices while protecting and isolating a portion of the membrane and maximizing workflow efficiency. The Weavr device suite also enabled labs to scale up Velvet test kit processing with a degree of workflow automation.

THE SOLUTION

At the start of the initiative, it was evident that the Weavr “Velvet” blood collection device needed several areas of system processing support. Areas of support included opening the Velvet device, accessing its membrane, and cutting from its many types of samples. This cutting operation also included assisting membrane sample placement into various test containers or well plates while creating a kiss cut to ensure sample traceability by not damaging the identification. Our early contextual research and user workflow analysis deepened two main observations. The first is that opening their blood sample kits was labor intensive, and second, there would likely be an extensive range of possible membrane sample types needed for various tests. These observations drove two focal insights: increasing opening ease and allowing for diverse sample cuts for various tests was vital for platform adoption by testing facilities.

These insights eventually became requirements around the automated opening of multiple kits at once, combined with a membrane punch device that could shape various samples and place them into test wells. With these accompanying devices, Weavr would have a test processing system to accompany their innovative blood sample collection device. This suite of devices would provide enhanced workflow and speed, giving Weavr a greater chance to win with processing labs.

THE PROCESS

Weavr needed expertise across a wide range of skills within the product development lifecycle. Uniquely, they required a device development team with depth in equipment design and process automation. Because of this needed range of expertise, Force-4 working in concert with SES, delivered value. From one perspective, the test kit openers and punch devices are hands-on medical devices with specific usability needs; from another vantage point, they are processing equipment focused on throughput.

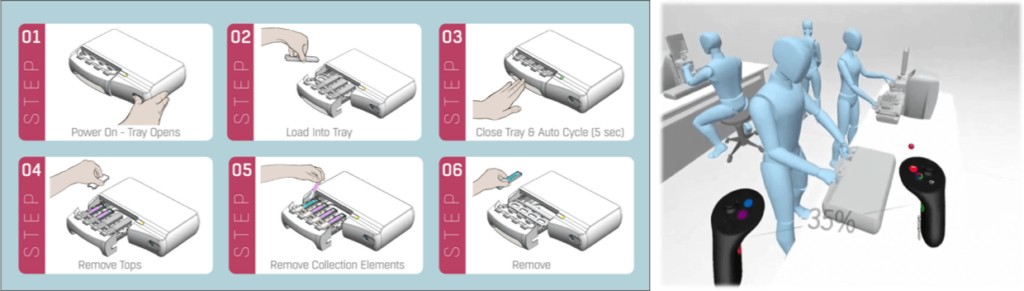

Our unique 3DS design process enabled SES Force-4 to outline a path to market with accuracy and speed as critical elements. A successful 2 Day Workshop kicked off the project where we invited several key members of the Weavr staff onsite to our headquarters. Through the workshop, we could dedicate time to getting to know our client’s customer and their product. It provided the opportunity to ask pertinent questions, understand their various issues, and explore viable solutions together. This workshop was invaluable as it created the foundation for a great customer while also establishing a thorough understanding of the user needs, requirements, and project direction moving forward. It underscored the requirement for the automated opening of multiple kits at once and a membrane punch device that could shape various samples and place them into test wells.

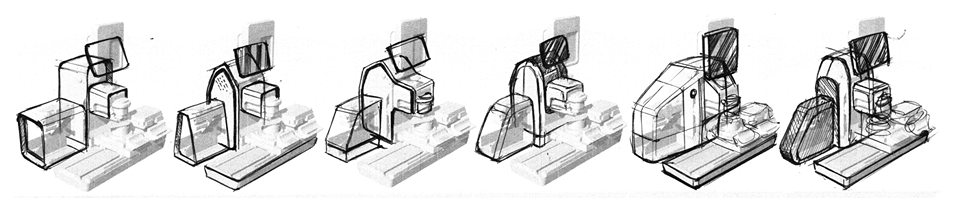

Once the team established requirements, we set forth to meet an extremely aggressive schedule to fulfill the needs of our client and the labs that support their business. Our Development phase provided a roadmap to leveraging years of design and engineering experience; our team developed three unique devices, from concept to working prototypes, that could be used onsite in processing labs in under five months.

We focused on providing a more efficient and enjoyable user experience for the lab technicians while enabling them to increase sample kit processing capabilities. We accomplished this by analyzing their current processing procedures and identifying critical areas to target, to mitigate user discomfort and improve productivity. Throughout the process, we often utilized virtual reality (VR) simulation to rapidly reference appropriate scale and workflow context. These contextualization tools provided a working atmosphere to quickly evaluate the products and assess whether the devices could be operated in both seated and standing positions and integrated into their natural working environment. We were able to design a simple tool that provided a comfortable grip and required minimal force and motion to open the sample kits manually. We engineered an electric opener for high-volume labs that completely automated the kit opening process, negating discomfort, and increasing kit processing by 500%.

SES Force-4’s Industrial Design team generated a device design language that communicated ease of use and broadened Weavr design equity connecting design cues already present in Weavr’s Silk test kit with an enhanced family of forms for user interaction and visual identity.

The product design language system throughout the suite of products established a family of form and brand identity for the Weavr product line moving forward. The entire suite of products was designed with the end user always in mind to eliminate fatigue and discomfort while increasing productivity to meet the demand for high-volume sample kit processing.

THE IMPACT

We developed a suite of lab equipment focused on opening the Velvet blood collection kits, consisting of a Manual Velvet Opener, an Electric Multi-Velvet Opener, and a DBS (Dry Blood Sample) Punch to expedite the processing of membrane samples in an effortless streamlined manner. The Manual Opener allowed small-volume labs to open the Velvet kit by simply pushing them through the device to separate the Velvet housing and provide easy access to the membrane samples offering a fast and pain-free process.

The Electric Multi-Velvet Opener automated separating the Velvet Kit housings and allowed lab technicians to open four kits simultaneously in a 5-second timeframe, dramatically increasing processing efficiency and throughput. The feedback received was overwhelmingly positive, as the lab managers were impressed with the ease of use and a significant boost in productivity.

The DBS Punch and Electric Opener are next to each other, allowing the lab technicians to quickly cut out and place blood samples in a receptacle of their choosing, typically either a petri dish or 96-well tray for post-processing and testing. The DBS Punch features an easy-access punch anvil for placing membrane samples with a keyed glide rail system to align the membrane sample quickly and accurately. It also has interchangeable punch heads, a camera with a heads-up display to visually verify punch sample location, and safety sensors to prevent injury or inadvertent activation of the punch head. The entire device was designed with accuracy and efficiency, making the cutting and processing of blood samples streamlined and expedient.

Our unique ability to fuse Human Centered Design with automated equipment at a rapid pace ultimately made the project successful. Taking advantage of the available COTS systems and utilizing PD best practices allowed user-centered needs like workflow analysis to guide contextual learning early and bring insights to the electro-mechanical machine design. The devices developed provided a great user experience for the lab technicians and allowed Weavr to exceed the expectations of the processing laboratories. These devices enabled labs to improve productivity by over 500% going from 120 kits per day to 650 kits per day. The Weavr device suite equips labs to keep pace with the throughput required to meet the needs of the ever-increasing macrocosm of home healthcare.

Ultimately, the lab suite produced a consistent and efficient way of opening Velvet devices and preparing samples for extraction, allowing labs to scale up without needing additional personnel while delivering an elegant and user-friendly customer experience.

Force-4 — Smart Ideas for A Smart World. We are a force for innovation because we envision and translate brilliant ideas into highly experiential and efficient products. Our expert team of strategists, industrial designers, and engineers unlock new ideas while navigating complex technical challenges to take your product to market faster.

Stress Engineering Services — Innovative Solutions for Cutting Edge Ideas. Our passionate, multidisciplinary team of expert problem-solvers believes that the future of innovation requires forward-thinking solutions and a tenacious commitment to cutting-edge ideas. Therefore, we commit to providing the most comprehensive design, analysis, and testing services with unsurpassed engineering integrity and expertise.

SES Force-4 is a forward-thinking expert team with in-depth technical knowledge, proven device development, and automation solutions.

AUTHORS

- Clint Haynes, founder of the Cincinnati office of Stress Engineering Services, has steadily grown the Cincinnati practice area while introducing breakthrough capabilities. He has a specialized focus on areas of medical, outdoor, and product innovation.

- Jason Phillips, Group Creative Director, has more than 20 years of innovation and product development experience in consumer-packaged goods, durable products, human performance applications, and technology integration.

Ref: C007-ED-A New Blood Collection Device for Diagnostic Testing

Keep in touch with us.

Sign up for our newsletter.