SES/Force-4 Microbial sealing is the core design tenet of pharmaceutical drug delivery systems (combination products), medical products and devices, and food and beverage packaging, as well as the rapidly growing segments of drug delivery and wearables. Regardless of the application, the seal between two discrete parts is the most vulnerable region of the primary boundary that serves to maintain product efficacy by preventing microbial ingress through the sterile barrier.

Developing, testing, and validating sterile barrier sealing systems (SBS) is a significant challenge because legitimate microbial pathways are very small. The leak path hole size typically will range from sub-micron dimensions to a few microns. Test methodologies that are based on pressure/vacuum decay or bubble leak testing are fraught with problems. Specifically, the pressurization or vacuum needed to drive air through a leak path so small can result in deformation of the components that do not exist in “real world” conditions of use, where microbial contamination occurs. Pressurization influences the outcome.

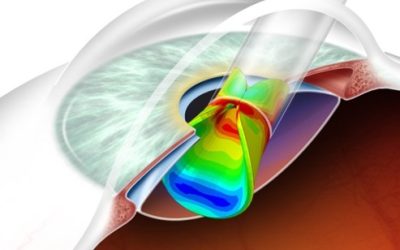

The preferred method of evaluating the performance of a device or package is to use helium rather than air to establish the size of the pathway.  The helium molecule is so small very little pressure differential is needed, which eliminates the artificial distortions that are caused by pressurization. Stress Engineering Services and its product and machine development group, Force-4 (SES/Force-4) have developed helium leak test equipment that enables very low-pressure assessment of leakage flow rate and calculation of the leak path size (Figure 1). The Helium leak tester (HLT) is proven to be effective in applications requiring data for:

The helium molecule is so small very little pressure differential is needed, which eliminates the artificial distortions that are caused by pressurization. Stress Engineering Services and its product and machine development group, Force-4 (SES/Force-4) have developed helium leak test equipment that enables very low-pressure assessment of leakage flow rate and calculation of the leak path size (Figure 1). The Helium leak tester (HLT) is proven to be effective in applications requiring data for:

- regulatory submissions

- quality control in production

- failure investigation

Helium Leak Test Applications

The most common forms of sterile barrier sealing (SBS) systems include mechanical engagement and thermal heat sealing seals. Each sealing approach has its advantages and disadvantages depending on the design and application.

Mechanical Contact Sealing Systems (MCSS)

Mechanical Sealing Systems include, “plug” seals, “claw” seals, and “nub” seals. Each of these mechanical seal types relies on the ‘contact pressure’ between the mating components to create a seal. The magnitude of the contact pressure required is dependent on the material properties of the mating components, the design of the seal, and the surface finish of the injection molded components (Figure 2). The primary benefits of mechanical contact sealing systems are that they can be designed to require relatively low force for user engagement (e.g., twisting, squeezing, pushing, pulling) and frequently are low cost, and can be designed to be very compact requiring little design real estate. Other forms of mechanical contact seals include liners, gaskets (Figure 3), and co-injection molded contact surfaces. These can be very robust sealing technologies but are frequently plagued with multiple microbial ingress paths, add component or manufacturing complexity, and require additional design real estate and high removal/separation forces.

Thermal/Ultrasonic/RF Sealing Systems (TSS)

Thermal sealing systems are among the most robust available in product and package design and are characterized by the “elimination” of the microbial leak path by locally melting a bonded sealing layer of a flexible film onto a sealing surface of the product, wearable, or device (Figure 4). TSS systems add an additional component, a heat sealable film to the bill-of-materials as well as an additional unit operation(s) in the manufacturing process. Another drawback of the heat-sealed lids as a primary sterile barrier is the increased possibility of generating particulate during removal.

It’s About Safety

If you need a microbial seal, it must work on every package, product or device, and must accommodate the many forms of variability the exist in a manufacturing environment. The design, the materials, and the process must collectively deliver a successful barrier, all the time. The HLT machine developed by SES/Force-4 has a lower cycle time than other helium leak testing hardware and is customizable to a wide range of applications.

AUTHORS

Jay Z. Yuan – Principal – Supervisor, Nick Molitor – Associate II, Clint Haynes – President of SES Force-4, Patrick Harrell – Senior Associate

Reference: New Helium Leak Test Equipment to Quantify Sterile Barrier Leak Path Size – B012-FDA

Keep in touch with us. Sign up for our newsletter.