Jay Z. Yuan, Clinton A. Haynes

Stress Engineering Services, Inc.

Sustainability is the Driver for Flexible Packaging

Sustainability is an important global environmental topic and a growing area of packaging-related innovation. Challenges and Opportunities in Sustainable Packaging Today | Packaging World Flexibles offer reduced waste alternatives relative to rigid packaging and typically result in a 5 to 10 times lower packaging-to-product ratio. This lower ratio enables more efficient packing of trucks for distribution, thereby reducing carbon emissions. Another component of the sustainability equation for flexibles is food preservation. Reducing food waste is a significant component of the flexible’s sustainability advantage. (Key Sustainability Facts – Flexible Packaging Europe (flexpack-europe.org)

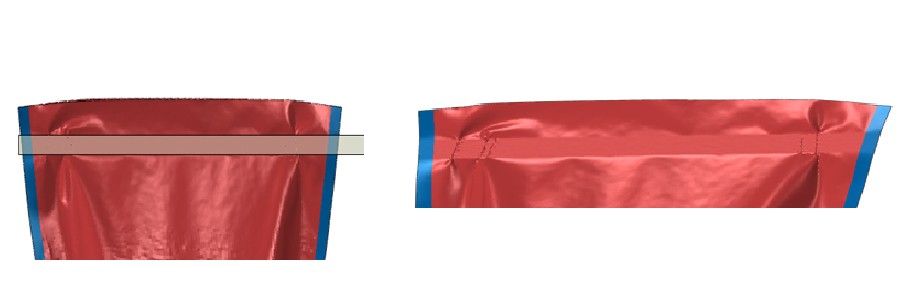

The range of applications of flexible packaging in the United States is expanding. One of the most important tenets of sustainability is to lightweight primary packages by using less material. Innovations in film structures and design have enabled the adaptation of flexibles into the very challenging applications of hot-fill sterilization, retort sterilization, and microwave-ready food packaging (Figure 1). These materials and structures offer an exciting path to improved sustainability provided they are not required to support any significant stacking-type loading.

Figure1. Examples of flexible pouches in the food industry

Structural Challenges of Flexible Packaging Performance

Although flexibles create opportunities for material waste reduction, emissions reduction, and enhanced food preservation, they are disadvantaged as structures when they are required to carry loads, like stacking. Their flexibility and irregular shape drive critical requirements for the secondary packaging systems to ensure safe distribution. The manufacture of a flexible package also introduces unique challenges that must be overcome.

Because flexibles are formed of a film (a membrane structure) they have very little strength in situations involving bending, which can result in structural instabilities and wrinkles. Designing for and around these characteristics is a challenge, which creates an opportunity to use computer-based modeling and simulation to understand and accelerate the development of flexible packages. This white paper includes 6 case studies to illustrate how modeling and simulation are used in the development of flexible food packaging. The principles described here also can be applied to all forms of flexibles including doy packs, stand-up pouches, pillow packs, gusseted pouches, liquid pouches, three-side seal pouches, dispensing pouches and other forms of flexible packaging. What Are The Different Types Of Flexible Pouches? (industrialpackaging.com)

Accelerate Flexible Development using Modeling and Simulation

The use of computer-based modeling and simulation tools to develop and optimize rigid packaging design has become more-or-less mainstream among major consumer product, medical, pharmaceutical companies, and packaging manufacturers. These modeling and simulation methods cover a wide range of supply chains, from injection/blow molding, filling, capping, sterilizing and stacking to consumer handling. However, the application and use of computer-based simulation methodology in the flexible domain is new. The 6 case studies below describe how predictive digital modeling and simulation methods have been used to accelerate flexible packaging development by providing a physics-based understanding of the challenge and enabling the creation of procedures and solutions in a virtual development environment.

Case 1 – Venting Seal Bar Design for Microwaveable and Retortable Pouches

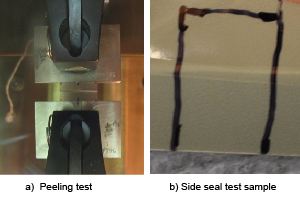

One of the key challenges of the venting seal bar design is the bonding needs to be strong enough to withstand high temperatures (~250°F) and pressures (15-25psig) in the retort sterilization process without leaking while remaining weak enough to break/debond within 60-90 seconds of microwave heating to initiate the venting (food temperature ~210°F and pouch internal pressure 4-5psig). When modeling this behavior, however, the main difficulty is to develop an adequate debonding initiation and propagation model, a failure model, in simulation terminology. A reasonable failure model can be generated and calibrated through peeling tests with different peeling angles (Figure 2). The test samples can be easily extracted from the side seals of representative or prototype pouches and the test can be performed using typical tensile test machines; however, a special fixture needs to be fabricated to facilitate testing at different peeling angles.

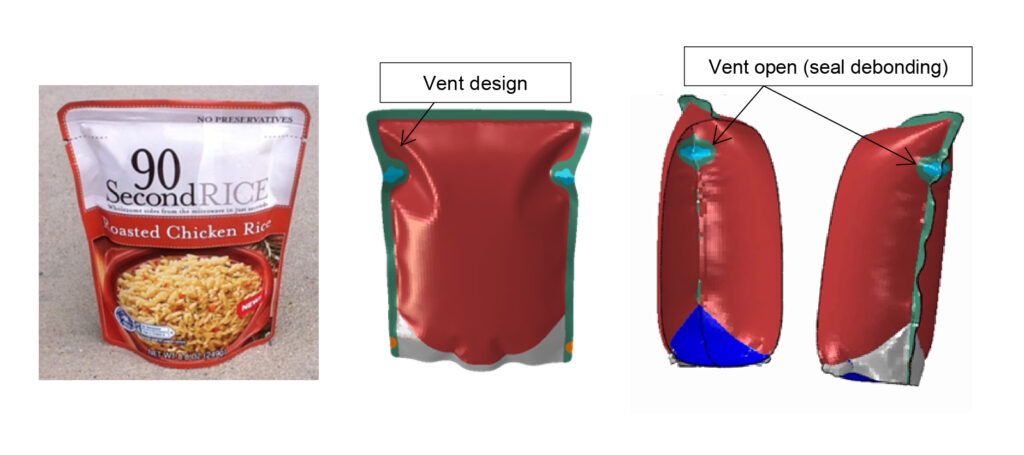

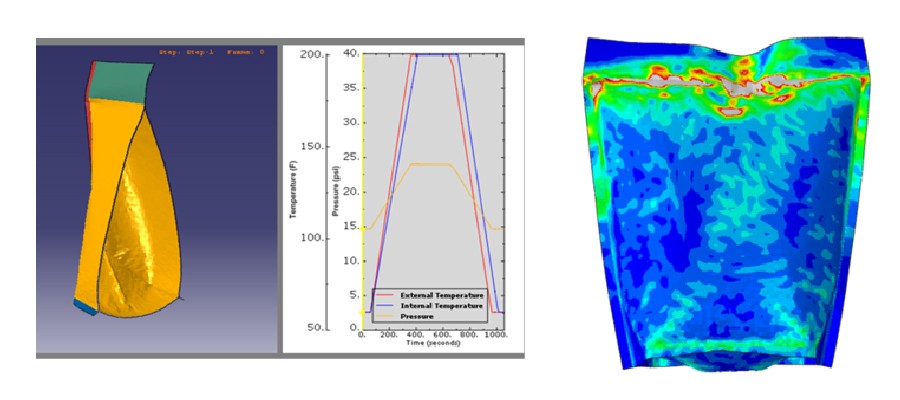

Once the heat-seal debonding failure model is generated, the simulation of the retort and a representative microwave process can be completed. (Note, the microwave heating process is approximated by specifying an empirically derived pressure, and temperature-time history. This approximation has proven to be a reasonable estimate of the primary loading and avoids the complexity of using an alternate computational approach to solve Maxwell’s equations at high frequencies). The microwave heating analysis of the 90 Second Rice pouch (Figure 3) predicts the vent should break at 4.2psig, while the test average is 4.5psig.

Figure 2. Peeling test of a strip of bonded pouch layers cut from the side seal of a pouch

Figure 3. Microwave venting simulation

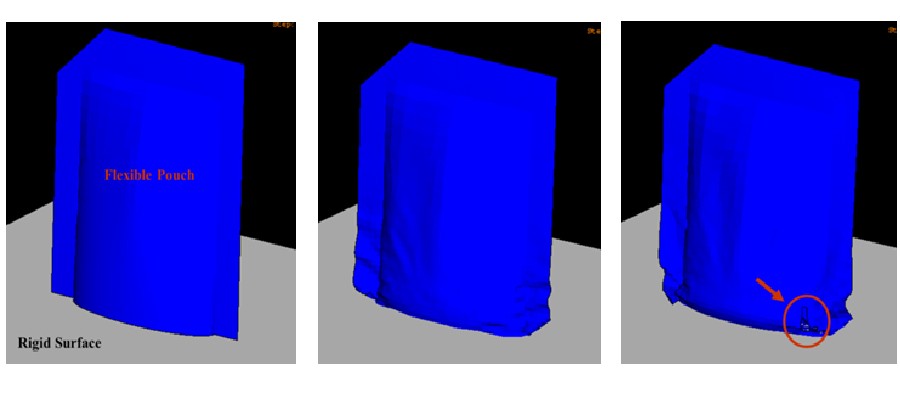

Case 2 – Stand-up Pouch Filling Simulation

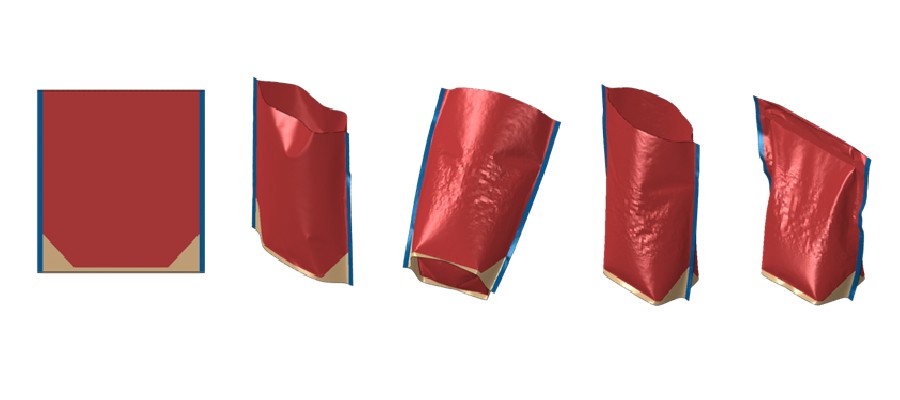

The presentation of the empty pouch to the filler and heat-sealing equipment is crucial in maintaining the efficiency of the line and minimizing downtime. The analysis of the pouch filling line, beginning with folding, followed by opening for filling, stand-up base opening, liquid/solid filling and heat sealing are simulated. The transfer from unit-op to unit-op is also modeled. The analysis in (Figure 4) can be used to determine the optimal locations of the side suction cups, the magnitude of the air pressure blast to open the package for filling and grip location/method to transfer the pouch. The fill capacity of the pouch is calculated based on the three-dimensional pouch shape, prior to filling. High-speed video has been used to evaluate and validate the methods used to approximate these critical behaviors, with good success.

Figure 4 Pouch filling simulation

Case 3 – Pouch Heat Sealing Simulation

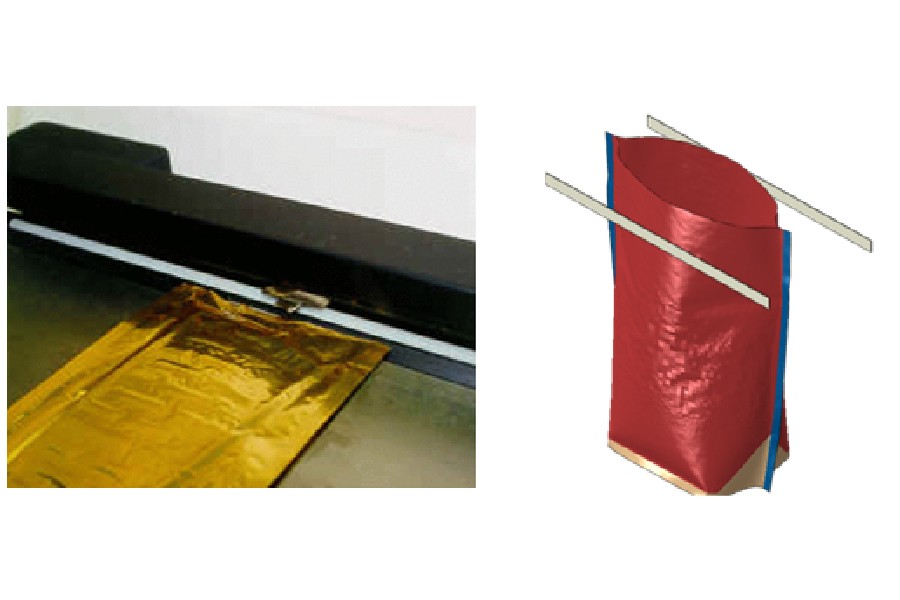

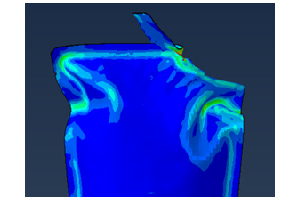

The focus of this study is the making of the top seal (Figure 5). The objective is to generate a top seal that is strong, leak-free, smooth (free of wrinkles), has minimal air or liquid pockets and is free of product contamination. To maximize the pouch filling capacity, the top of the pouch is often in an oval shape prior to being transferred to the heat-sealing station. Clamping a three-dimensional oval opening into a two-dimensional flat top seal without wrinkles is not trivial. The simulation model in this case study successfully captured a wrinkle caused by improper transferring grips (Figure 6). Based on this initial learning, similar methods were used to develop alternate grip locations to mitigate wrinkling.

Figure 5 Heat seal simulation

Figure 6 Wrinkles/folds predicted by the simulation

Case 4 – Retort Sterilization Simulation

Depending on the retort sterilization process, high-internal pressure can be generated due to the thermal expansion of the air/gas in the headspace of the pouch. This often occurs during the cooking period of the retort cycle, when the temperature is highest (~250°F). An extended cooking period (5-10 minutes) presents an additional challenge to the seal integrity due to the material’s creep behavior. The simulation in this case study focuses on the pouch seal bar integrity, generally similar to the venting design case (Case 1). Therefore, the bonding failure model is one of the key elements of the simulation; however, instead of generating a failure model at room temperature, the elevated temperature and time-related creep effects must be taken into account. This analysis simulates the entire retort cycle from the rise in temperature/pressure and cooking to the cooldown (Figure 7). The results determine the hot spot locations and provide directional input, which the design team can use to size the seal bar and optimize the design.

Case 5 – Pouch Drop Impact Simulation

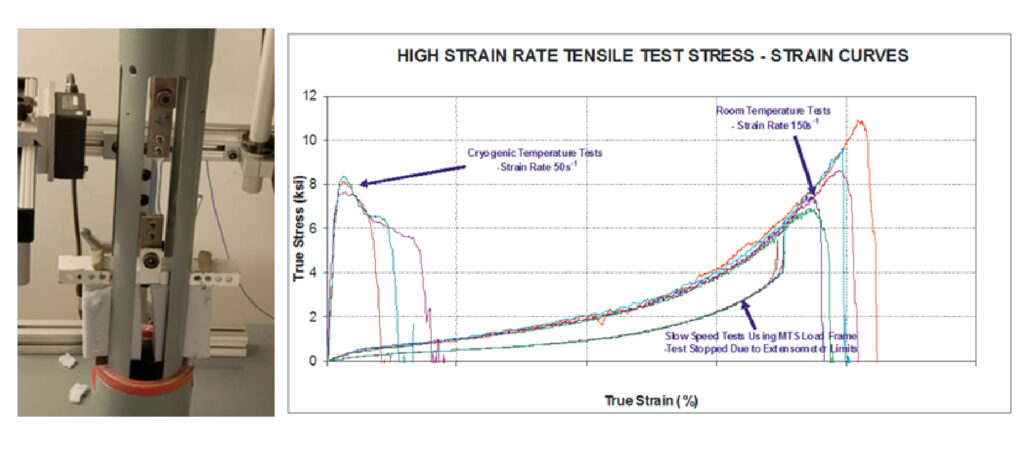

Package failure resulting from dynamic events, such as the dropping of a filled pouch, can be captured by simulation. Again, the material failure model for the film is of paramount importance to the completion of a successful simulation. However, unlike the previous two cases (Cases 1 and 4); the critical material performance attribute is ductility under high-strain rate loading and ductility under biaxial stress. For a 3-foot drop event, the peak strain rate at the point of the impact can be as high as 30 in/sec, which is about 100x of the normal tensile test speed (2 in/min crosshead speed).

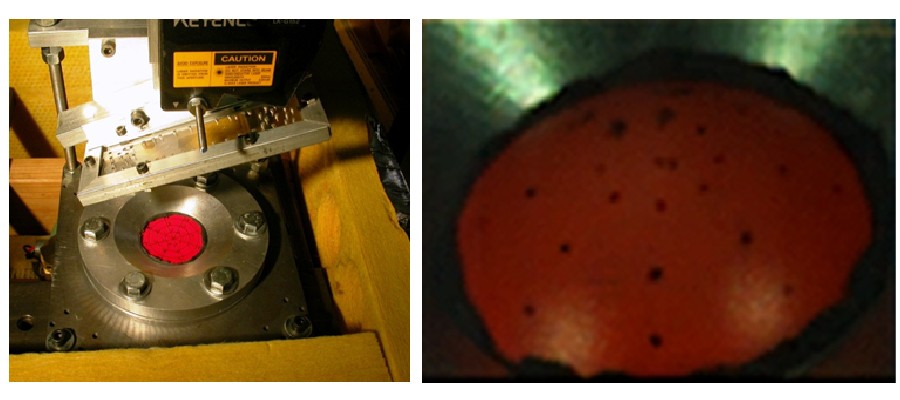

In general, plastic/composite films are very sensitive to strain rate and stress states. Characterizing the pouch film properties at high-strain rates and biaxial stress states is not trivial. The custom test fixtures illustrated in Figures 8 and 9 have been used to generate the specific data needed to characterize the film performance. The tests were performed at various strain rates, under equal biaxial stress and under uniaxial stress, after which a stress state-dependent material model was created. This is very important because the strain rate and stress state are different for each location on the pouch during the impact event. Accurately capturing the material behavior is crucial in reliably predicting the location of the failure and the height at which it occurs. (Figure 10)

Figure 8. Customized high-strain rate tensile test machine and test data

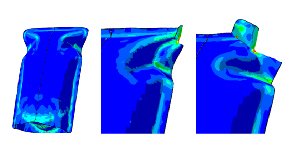

Case 6 – Pouch Tear-Opening Simulation

Consumers become annoyed when tear-opening features fail (Figure 11). It is not uncommon for a consumer to have to make a second or third try or use scissors to fully open a pouch that does not contain an opening fitment. Computational methods can be used to predict the performance of tear strip opening features, provided a material model is developed that captures the salient material behaviors. In the previous examples, such as cases 1, 4, and 5 above, the focus was on the failure initiation. However, for the tear-opening simulation, the failure model needs to accurately capture the failure propagation long after the initiation. In situations where the film is exposed to long periods of thermal exposure, such as a retort, the material behavior often changes. It has been observed that the material ductility can reduce significantly and become much more sensitive to the load path, tearing force and top seal variation. This requires the development of the material model be based on thermally processed materials. When this is done, experience indicates that the pouch tear-opening simulation can provide directional input to the design of the opening feature (Figures 12 and 13).

Figure 11. Tearing gets off the dotted line

Figure 12. Tear-opening simulation – an off-line tearing

Figure 13. Tear-opening simulation – a straight line tearing

The Future of Sustainable Packaging Development

Predictive computational methods are at the core of sustainable package development in the construct of Industry 4.0 and the digital transformation of the packaging industry. The next industrial revolution: Packaging and ‘Industry 4.0’ – (packaging-gateway.com) Over time, the democratization of simulation methods will significantly reduce costs and expand the availability and access to all organizations. The critical role of the engineer/package developer will be the interpretation of the data to maximize its value to the development process. In this future state, as the predictive tools gain acceptance and are used more, the engineer will be aided by deep learning, data analytics, and artificial intelligence algorithms that are derived from the growing universe of packaging applications.

Ref: W003-SP-Accelerate Sustainable Flexible Package Development

Keep in touch with us.

Sign up for our newsletter.